18th, March: Global Recycling Day 2022

Pellenc ST highlights 4 innovative projects for improving the plastic sorting performances, including trays and bottles, for recycling.

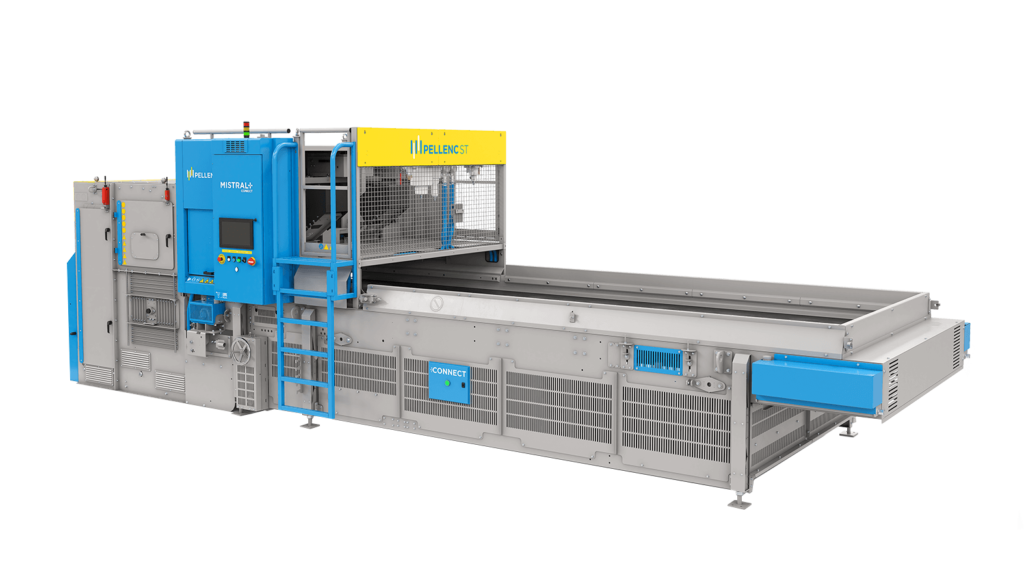

Mistral+CONNECT

Biffa Aldridge

Design for Recycling

HolyGrail2.0

Mistral+ CONNECT intelligent and connected sorting machine for the recycling industry.

This new intelligent and connected sorting machine meets the new 4.0. sorting plant standards.

Equipped with the latest “FLOW detection” spectrometer, which ensures unmatched sorting performance, this new generation of optical sorters is equipped with a series of connected sensors that provide more visibility on the complete “Full Package” system.

Combined with the Pellenc ST field expert service (one year service included), the collected Smart&Share data allows operators to better target corrective actions in order to improve plant availability and sorting quality.

Pellenc ST supports Biffa Aldridge to double recycling capacity with Mistral+ CONNECT.

Waste management company Biffa, one of UK leaders in closed-loop plastic recycling, has doubled the plastic recycling capacity at its Aldridge materials recycling facility (MRF) in the West Midlands.

Built in 2008, Biffa’s Aldridge MRF diverted 300,000 tonnes of waste a year from landfill by turning it into saleable commodities. In addition to plastic bottles and containers, the facility can process aluminium and steel cans, as well as glass bottles and jars from a household recycling stream.

To increase its recycling capacities, Biffa partnering with Turmec decided to upgrade its plastic bottle sorting line and install latest generation Pellenc ST Optical Sorters for higher material recovery and recycling.

Expertise and Technology Sharing

by Pellenc ST helps Redesign Recycling

- Our leading position in this economy gives us an overview of the material recovery industry, and especially the key steps of collection, sorting and recycling.

- Since 2016, environmental impacts are increasingly questioned, especially in the domain of packaging: The Single-Use Plastic Directive (SUPD – June 2019) requires that all packaging be recyclable by 2025, and requires a minimum of recycled content in their composition.

- Before being recycled, every product needs to be first collected and then sorted. So, we help with our technology and expertise all circular design stakeholders such as green dot organizations, brand owners, packaging designers, label & ink manufacturers, as well as Material Recovery Facility (MRF) operators and recyclers.

- In 2021, we created a department entirely dedicated to this topic. It makes our expertise on materials and associated detection technologies available, as well as our knowledge of our customer sites, whether they are MRFs or recycling centers.

Holygrail2.0 : the digital watermarking initiative to revolutionize plastic packaging recycling

Phase 2 of the Digital Watermarks initiative #HolyGrail2.0 project with Pellenc ST sorting prototype has been a great success here at ARC – Amager Ressourcecenter in #Copenhagen.

Over 700 people representing the #packaging value chain have joined the Open House sessions showcasing the sorting of digitally watermarked packaging (350 SKU).

For those who have not been able to join, watch this video footage showing material preparation and live sorting.