PENN WASTE, PA

The Case Study of a Plant Refurbishment

Penn Waste, a waste and recycling company serving South Central Pennsylvania, proudly operates a state-of-the-art recycling facility spanning an impressive 96,000 square feet in York, PA. As part of the Waste Connections family of companies, Penn Waste has been a leader in the industry since they were established in 2000.

Unfortunately, in 2022, their recycling plant suffered a devastating fire that destroyed its equipment, forcing the recycling company to rebuild their system. For the reconstruction of the container line, Penn Waste entrusted the project to integrator Van Dyk Recycling Solutions and decided to renew its confidence in Pellenc ST by replacing its 6 optical sorters lost in the fire. Exactly 363 days after the initial fire, the recycling facility reopened a modernized- and decidedly more high-tech – MRF. Today, the facility is one of the most advanced in the country in terms of performance. But what are the keys to this success?

Install Equipment Easy to Maintain

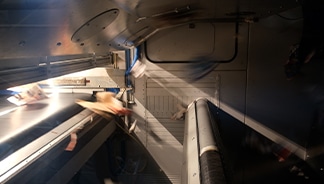

Mistral+ CONNECT shares the robust all-in-one design concept of the Mistral+ Full Package. This equipment, which is TÜV Rheinland certified, combines a rapid conveyor belt with a detection system and an output box to guarantee quality all along the sorting value chain. During the development phase, Pellenc ST pays particular attention to simplify the work of operators to optimize maintenance costs. Designed as a complete ergonomic system, the machine is simple to install and offers safe and easy access to operators. Thanks to the platform access, they can safely enter the output box for maintenance operations and no longer need to stop the line to clean lights or scanners. Thanks to this new generation of machines, maintenance time has been considerably reduced.

Meet New Sorting Standards

With growing demands in terms of quality, this plant retrofit aimed to guarantee at least thesame sorting capacities while increasing industrial performance. So, for Penn Waste acquiring the most advanced technologies on the market was essential.

Now, there are 6 brand-new Pellenc ST optical sorters on the container line to help in the recovery of valuable fractions: PET, HDPE, PP and mix plastics.

Equipped with the latest hardware and software innovations developed by Pellenc ST, Mistral+ CONNECT was the suitable machine for this project. It offers improved performances, using the new “FLOW” detection system which combines a new spectrometer with an extended NIR/VIS spectrum and focused illumination. This combination enables the recovery of waste to high levels of purity. The new sorting line makes things more efficient. Thanks to their investment in upgraded equipment, the Penn Waste has witnessed a notable boost in throughput, capture, efficiency, and purity. For example, Pellenc ST machines can achieve the fine separation between natural and colored HDPE with ever greater performance in terms of purity and efficiency.

Moreover, Pellenc ST machines are now “Future Proof”. Thanks to the CNS “Central Nervous System” software platform, operators will be able to integrate future technologies and Pellenc ST scanners such as the IIoT, Watermarking and Artificial Intelligence in the form of upgrades.

Reduce Energy Consumption – TCO

The new range of Pellenc ST machines stands out with its low energy consumption. Maintenance costs have been minimized. The replacement rate for parts has been considerably reduced, and the best example is air consumption, which has been cut by 30% compared to previous ranges of machines. Against a backdrop of intense energy pressure, these unique market features are decisive in the choice of an optical sorting supplier.

Get Ready for 4.0 Industry

With the Smart&Share application, Pellenc ST optical sorters are now Industry 4.0 compatible. With this invaluable performance support tool, Penn Waste benefits from real-time data about the operation of machines and helps optimise their maintenance operation with intelligent alerts and customised reports for increased availability and better sorting quality.

The Pellenc ST design allows our mechanics to safely access the equipment to perform their duties. The Pellenc ST opticals are exceeding our expectations.

Shawn Querry, Plant Manager

A BREAKTHROUGH DESIGN OF THE EJECTION HOOD