A team of experts at your service

A shared objective: boosting our customers performance

With more than 2500 machines in 40 countries, Pellenc ST has a network of technicians specially dedicated to customer satisfaction. Our sales and customer service teams provide their expertise and assistance to all our partners to keep their sorting lines operating optimally. Our after-sales service is available 24/7 and travels around the world to ensure a high level of efficiency and availability.

PERFORMANCE

SUPPORT

PROXIMITY

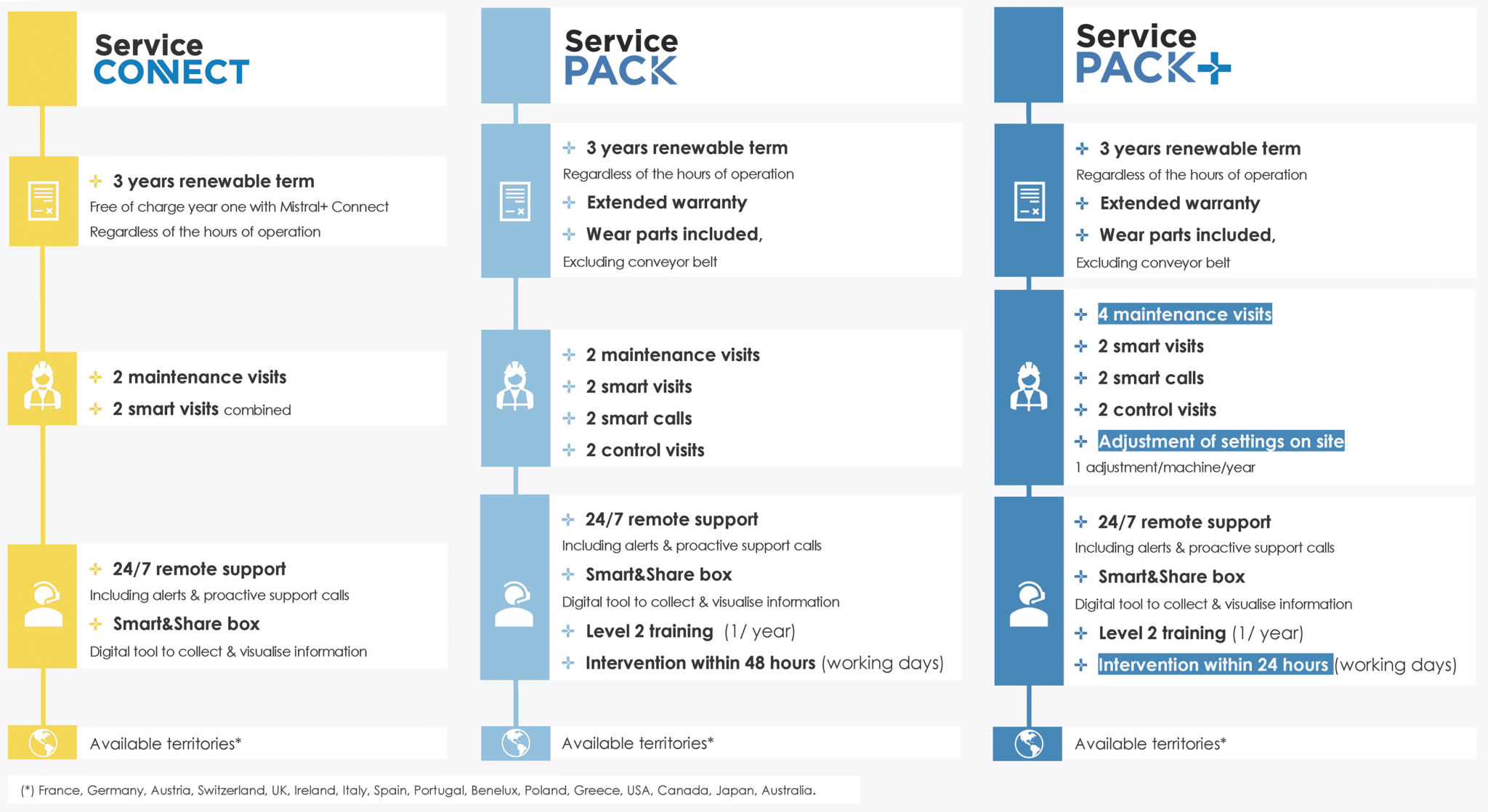

Service Connect: the new all-in-one, connected solution

Service Connect guarantees our customers the highest level of service, as well as the provision of personalised reports and analysed information during maintenance visits. New for 2021, Pellenc ST systematically includes one year of 24/7 on-site and remote services with the purchase of a Mistral+ Connect.

- Provided by our local experts

- 90% of calls are resolved remotely

- New Intelligent alert monitoring

- New Preventive calls

Local support

- A team of 5 experts deployed throughout UK

- High reactivity

- Parts available quickly

Service PACK

Service PACK: the turnkey and connected solution to maximise operating performance and keep costs under control

Pellenc ST has reinvented the service approach with the launch of an all-in-one solution: the Service PACK. This solution is designed for operators of sorting or recycling centres in search of a straightforward and comprehensive service to give their performance a boost. The Service PACK combines traditional 24/7 services, unlimited supply of replacement and wear parts, and advice based on analysis of the data collected by the digital system.

Smart & Share

Smart & Share is an intelligent, secure SaaS platform that enables sorting and recycling centre operators to analyse their sorting performance. It provides near real-time monitoring and control of optical sorters’ data via intelligent alerts and easy-to-read graphs. Once the data has been analysed, a personalised report is presented to our customers on their site by our local experts, so that they can share their findings, discuss them and together identify areas for operational improvement to enhance quality or yield.