Plastics recycling

Recovering all types of resins, even the most complex

Plastics recycling markets are increasingly demanding with regard to the quality of sorted materials. The latest European regulations on waste packaging ( Waste Package) and China’s ban to imports have heightened the need for better sorting and recycling of plastics. As the composition of the streams is constantly changing, new sorting challenges have emerged with materials that are complex to identify, such as PET trays, opaque PET, and multilayer PETs.

The main applications

PET RECYCLING

- Sorting PET bottles from PET trays

- Intelligent sorting by material and colour

- Sorting PET flakes

- More effective detection of the main contaminants (PVC, metals, opaque PET, trays, multilayer, labels, sleeves, etc.)

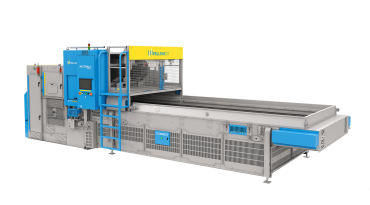

FILMS RECYCLING

- High-capacity sorting of PE films (Top Speed Option)

- Sorting by material and colour

- Sorting multilayer films

- Separation of aluminised films from bioplastic ones

OTHER PLASTICS

- Purifying a PE stream

- Purifying a PP stream

- Purifying a PS stream

- Sorting technical plastics

Our customer testimonials

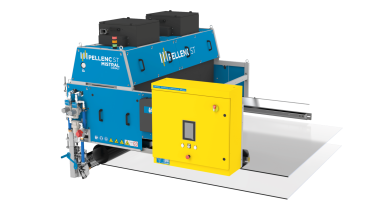

Daly Plastics, Zutphen: High-speed film sorting in the Netherlands

Founded in 1985, Daly Plastics B.V. has become one of the largest recyclers of plastics in the Netherlands. The company invested several million euros to build the most efficient film recycling plant in Europe. It uses 4 Mistral machines—each equipped with a “TurboSorter” stabilisation system—to purify the films and ensure optimal quality for the output streams. Daly Plastics surpassed its objectives when it boosted its operational efficiency and increased its capacity by more than 50%.

“Pellenc ST provides high capacity sorting without compromising on results”

Peter Daalder

CEO of Daly Plastics

Clear Path Recycling, Fayetteville, North Carolina: PET recycling in the United States

Clear Path Recycling is the biggest recycler of PET in the United States. The plant recycles more than 127,000 metric tons of PET bottles each year and produces PET flakes, especially for the fibre market. The company uses 10 Pellenc ST sorting machines to sort the bottles by material and colour in order to guarantee the highest level of purity of recycled PET.

Petstar, Mexico: the world’s leading Bottle-to-Bottle recycler

From the outset, the PET recycling plant has relied on Pellenc ST equipment to recover its bottles. It uses 6 Pellenc ST sorting machines to guarantee the purity of the streams and meet the quality criteria required for material intended for food-contact standards.