Waste sorting

Material, organics and energy recovery

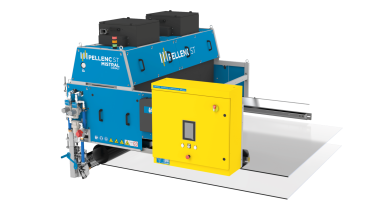

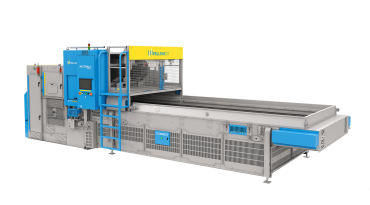

Waste sorting methods vary according to the nature of the material and the type of collection. To minimise the volume of waste material buried in landfills or incinerated, lawmakers are imposing increasingly ambitious targets in terms of waste recycling and recovery. Pellenc ST supports municipalities, sorting centres, and recyclers by offering high-performance solutions to meet their specific needs.

SELECTIVE COLLECTION

The main applications

2D FLAT BODY SORTING

- fibrous sorting: paper/cardboard and specificities (de-inking, mixed papers, graphic papers, etc.)

- Films sorting: LDPE recovery

3D HOLLOW BODY SORTING

- PET recovery: separating by colour and category (bottles/trays, clear and clear blue, opaque PET, multilayer, sleeves, etc.)

- Rigid plastics recovery: PE, PP, PS, food cartons, etc.

- Non-ferrous metals sorting: aluminium (cans, etc.)

Our customer testimonials

Suez Ölbronn: one of the largest sorting centres in Germany

“Suez has invested more than €20 million equipping this new facility with the latest technologies. The plant has integrated 23 Mistral+ machines into the process to recover materials in line with the most stringent regulations currently in force in the country. Suez Ölbronn is one of the largest sorting centres in Germany with an annual capacity in excess of 100,000 tons.”

Recology Pier 96: High-capacity paper sorting in the USA

Designed in partnership with the City of San Francisco, this plant sorts more than 300,000 tons of waste per year and is the leading supplier of used paper on the west coast. With 3 Mistral+ optical sorters on the fibrous materials line, the sorting center achieves record-breaking efficiency in North America with less than 1.5% contamination.

Biffa Edmonton: High performance fibre sorting in the UK

Biffa Edmonton processes more than 250,000 tons of waste each year. To optimise its efficiency, the sorting centre decided to install 5 Pellenc ST sorting machines on its fibrous line. The machines are equipped with “TurboSorters” to stabilise light objects. They make it possible to purify fibrous materials at high speed. As a result, the final purity rate exceeds 99% after the quality control stage.

Ward Recycling Hartlepool: Fibre sorting in the UK

The company decided to develop this plant in response to market trends. “As we are a small company and the Chinese and Asian markets have clearly become very difficult to maintain, we felt we had to do something in the UK,” says Nigel Booth, managing director of Ward Recycling. The company expects to process 100,000 tons of material each year from mixed fibre streams and separated papers/cardboards. 7 Pellenc ST optical sorters have been installed to purify the streams and supply Palm Paper, a paper mill, with high quality raw materials.

Mr. Mallinger, sales manager of Bollegraaf, had this to say about the optical sorters: “The machines are very adaptable. You can adjust the settings according to changes in the material you are processing.” This enables the plant to keep up with market developments.

Sietrem Saint-Thibault-des-Vignes: self-adapting sequential sorting

The new Sietrem sorting centre, operated by Veolia, can process up to 30,000 tons of waste material per year. The plant is equipped with cutting edge equipment—including seven Pellenc ST optical sorting machines—which lets it react more effectively to the new requirements of the extended sorting instructions.

A2A Cavaglia, Biella Province: state-of-the-art plastics sorting in Italy

With its 8 Pellenc ST optical sorters, the Cavaglia sorting centre has one of the most advanced processes in Europe for plastics recovery. The A2A Ambiente plant has a production capacity of 150 tons per day, i.e. more than 45,000 tons annually. The machines sort plastic by resin (PE, LDPE, PP, PET, PVC, etc.) and colour (clear blue, transparent, etc.) to produce a total of 13 recoverable fractions. The concept has been such a success that A2A has decided to open a second, identical plant in Muggiano.

Semardel, Vert-le-Grand, France: Industrial waste recovery and RDF preparation

Semardel invested €20 million in its orting centre dedicated to industrial waste. Its annual processing capacity is 230,000 tons. The plant uses 8 Pellenc ST optical sorting machines to recover materials (wood, fibres, plastics) and redirect them away from landfills by turning them into RDF with high calorific value.

Related products

MUNICIPAL SOLID WASTE

All the sorting methods used in selective collection can also be used to sort Municipal Solid Waste, thanks to adapted mechanical and optical sorting.

The main applications

MATERIALS RECOVERY

- Rigid plastics recovery

- Fibrous recovery

- Glass recovery

ORGANICS RECOVERY

- Application dedicated to methanisation and composting

ENERGY RECOVERY

- Removing contaminants

- Producing RDF with a high net calorific value

- On-line quality control (composition, LHV, humidity, biogenic portion)

Our customer testimonials

Lekaro, Warsaw: Sorting municipal solid waste in Poland

LEKARO is a family business that manages the collection and treatment of 360,000 tons of waste each year from the Greater Warsaw area. The municipal solid waste sorting unit is equipped with 6 Pellenc ST optical sorting machines on the 80-350mm fraction. The facility sorts plastics by resin (clear PET, blue PET, green PET, PE, PP, PS), paper/cardboard, and metals to achieve a recovery rate of 15% of the 180,000 tons of municipal solid waste received. The sorted fractions are sent to buyers in Poland or neighbouring countries. In addition, the plant generates high-quality solid recovered fuel from 35% of the incoming stream. The organics fraction is stabilised before being sent to a landfill.

Terna, Epirus: Sorting Municipal Solid Waste in Greece

With an investment of €52.6 million, the municipal waste treatment plant in the Epirus region is one of the most modern in Europe. It can process up to 105,000 tons of material per year. The plant operates 3 Mistral+ optical sorters in combination with mechanical-biological processes to recover six reusable fractions from the incoming stream, including PET, PE, mixed plastics, and paper/cardboard.

Urbaser, Casares: sorting municipal solid waste in Spain

Every year, the Urbaser plant processes 11,000 tons of waste from selective collection and more than 35,000 tons from municipal solid waste. The plant uses 5 Pellenc ST sorting machines in its process to optimise the recovery rate of PET, HDPE, bricks, etc.

Related products

INDUSTRIAL,

CONSTRUCTION & DEMOLITION WASTE

The main applications

HEAVY WASTE SORTING

- Purifying wood

- Sorting wood by grade

- Recovering rigid plastics

- Purifying a stream of inert materials

LIGHT WASTE SORTING

- Recovering paper/cardboard

- Recovering plastic films

- Generating a stream of RDF

Our customer testimonials

Semardel, Vert-le-Grand, France: Industrial waste recovery and RDF preparation

Semardel invested €20 million in its orting centre dedicated to industrial waste. Its annual processing capacity is 230,000 tons. The plant uses 8 Pellenc ST optical sorting machines to recover materials (wood, fibres, plastics) and redirect them away from landfills by turning them into RDF with high calorific value.

Ti Valo, Ploufragan, France: Sorting, material recovery, and RDF production

In parallel with the modernisation of the selective collection sorting centre, Kerval Centre Armor and Guyot Environnement have transformed the Ploufragan plant into a sorting and RDF production facility. By processing streams that had previously been untreated (bulky waste, compostable municipal solid waste refuse, industrial waste, sorted waste from selective collection), this new facility has succeeded in significantly reducing the volume of material sent to landfill sites.

The material & energy sorting and recovery centre is equipped with 6 Mistral+ machines that maximise the recovery of materials before producing RDF for additional energy recovery.