test and

training center

ed </ h2>

Design For Recycling Service

Expertise and Technology Sharing by Pellenc ST Helps Redesign Recycling

Facing the ecological crisis, our challenges are the dependency on fossil fuels, the elimination of waste from our environment, and the preservation of natural resources thanks to recycling.

![]()

For 20 years, Pellenc ST’s industrial sorting solutions have been promoting the emergence of a competitive and sustainable circular economy.

- Our leading position in this economy gives us an overview of the material recovery industry, and especially the key steps of collection, sorting and recycling.

- Since 2016, environmental impacts are increasingly questioned, especially in the domain of packaging: The Single-Use Plastic Directive (SUPD - June 2019) requires that all packaging be recyclable by 2025, and requires a minimum of recycled content in their composition.

- Before being recycled, every product needs to be first collected and then sorted. So, we help with our technology and expertise all circular design stakeholders such as green dot organizations, brand owners, packaging designers, label & ink manufacturers, as well as Material Recovery Facility (MRF) operators and recyclers.

- In 2021, we created a department entirely dedicated to this topic. It makes our expertise on materials and associated detection technologies available, as well as our knowledge of our customer sites, whether they are MRFs or recycling centers.

- We offer different types of services (see below). In addition, we realize design guidelines that aim to be distributed transparently to all circular economy players.

- This activity also allows us to anticipate the evolution of materials, and to include in our technology roadmap the innovations to be developed to satisfy the future sorting needs.

- Finally, we maintain close partnerships with technical or research centers specializing in each of the major material sectors. These partners can carry out recyclability tests on the products that we have sorted for them.

Some Present Challenges

- To maximize the capture rate and purity of the targeted recyclable materials

- To remove the non-recyclable ones to avoid contamination of the recoverable waste streams.

- To recover small elements (less than 80mm)

- Detectable blacks

- Multi-layer packaging

- Metallized Packaging

- Labels and sleeves

- Biodegradable plastics

Our Services :

Detection test

We check whether the standard machine settings used in sorting or recycling plants allow us to detect and send the product to the targeted outlet.

Standard sorting test

This test follows a standard protocol such as COTREP[1] (FR) or APR[2] (US)

Optimized sorting test

Samples are mixed with a representative household waste stream to test their sorting in real conditions. The protocol and/or settings can be adjusted according to the applicant needs.

Design for Recycling support

Discussions on the test report, packaging design adjustments, and/or training about good practices.

[1] COTREP : Center of resources and expertise on household plastic packaging recyclability (FR). COTREP has been supporting packaging designers for 20 years in the development of recyclable solutions.

[2] APR : Association of Plastic Recyclers (USA)

In all cases, a customized report is provided.

For further information, Contact-us

Test Center

Our Test Centers

850 sqm dedicated to sorting tests for waste, plastics, metal segments

Pellenc ST provides its customers and partners with an industrial demonstrator equipped with the latest intelligent sorting equipment to study the best sorting strategies and recover their waste stream.

The test centre in Pertuis is divided into 3 separate areas with 3 machines:

![]() TEST CENTER – PERTUIS, FRANCE

TEST CENTER – PERTUIS, FRANCE

These technologies enable packaging sorting, plastics recycling and also metals, WEE and plastics from ELVs sorting.

Equipped with a recirculation loop, these sorting lines can simulate several sorting sequences in field conditions.

Use our Test & Application Center to validate new sorting strategies. Our extert engineers will demonstarte how our new technologies can improve your production processes without interrupting your operations.

<h2 id=”CentredeTests”> CTF </ h2>

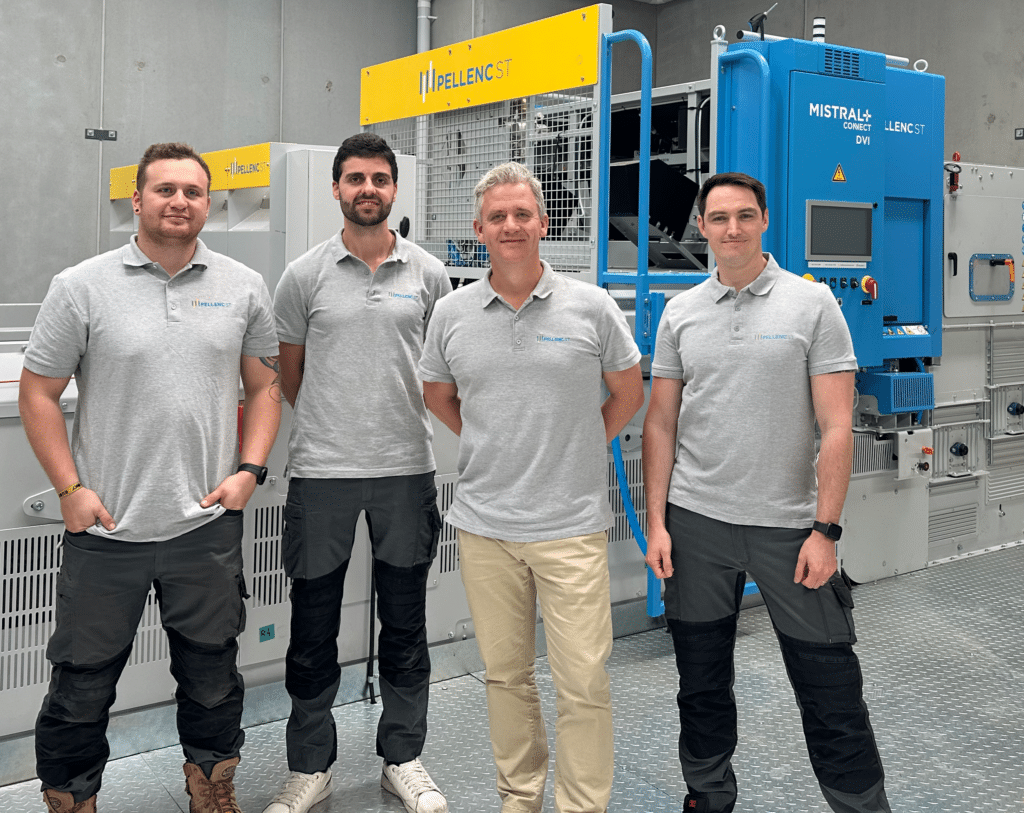

Training Centre

Our customers and partners training sessions are performed by Pellenc ST technicians. With years of experience, they like to share their knowledge and know-how to provide the keys of an optimal use of optical sorters.

Discover our customized training courses:

- Available to all our customers and partners

- Available for all machines generations

- In the customer’s language

- According to defined and personalized programs

![]()

TEST CENTER – USA

![]()

TEST CENTER – JAPAN

![]()

TEST CENTER – AUSTRALIA

For further information, Contact-us

The Pertuis Test Center is available for our international customers & partners for Eco-Design requests.