A Franco-French success story!

For over ten years, France’s leading manufacturer of optical sorting machines, Pellenc ST, has been working closely with Semardel and its operating companies Semaval and Serivel. Nearly 30 optical sorting machines now equip the WEEE processing and selective collection facilities at the Ecosite de Vert-le Grand / Écharcon. A look back at a Franco-French success story.

Managed by Semardel, the 150-hectare Ecosite de Vert-le-Grand / Écharcon in the Essonne region of France concentrates all waste recovery processes (storage facility, biomass platform, UVE, BTP sorting, DAE and bulky waste sorting, selective collection sorting, etc.). With 1.4 Mt of waste collected in 2021, of which 194500 tonnes will be recovered from materials and 449000 MWh from non-recyclables, “the best part of each tonne of waste that enters here is recovered to its maximum potential”, sums up Eddy Dumont, Managing Director of Serivel and Semaval, the entities operating the selective collection sorting center and the WAS sorting center. “With this in mind, each of our processing facilities is designed and regularly upgraded to meet both regulatory and technical developments.

We are constantly improving our various processes to keep them at the cutting edge of technology. It is in this context that Pellenc ST, the French leader in optical sorting, has been working for over ten years in partnership with the Ecosite’s two main sorting facilities: Semaval and Serivel. “When we talk about partnership, we’re not just talking about a partnership, because with a cumulative total of 28 Pellenc ST sorting machines, these facilities represent our largest fleet of machines in France. And we’re not just talking about the equipment used, but also about working together to develop and technically validate new technologies”, emphasizes Marc Minassian, Pellenc ST Sales Director for France.

Eight machines at Semaval

A synergy that began in 2012 when, following a fire at the sorting center for commercial waste operated by Semaval, the latter had to rebuild the facility. Contrary to the choice made for the original plant, while retaining the identical process for a capacity of 200,000t/year, the operator opted for Pellenc ST technology. “That’s how the first seven Mistral optical sorting machines were integrated into the sorting line for the material recovery of WAS and a production capacity of 50,000t/year of CSR from sorting rejects,” explains Manuel Cristino, Semaval’s Operations Manager.

Two years later, in 2014, when the development and prototyping phases of the new Mistral+ sorting machine had been finalized at its headquarters in Pertuis, Pellenc ST, looking for industrial partners ready to test the robustness, stability, reliability and new maintenance features of its machine, approached Semaval. “This collaboration implies a high level of trust between the two partners, with the operator taking a certain amount of risk, since it is he who tests the machine under industrial conditions on the site, with his own production requirements”, admits Marc Minassian. Nevertheless, Semardel and Semaval played the game and integrated the first Mistral+ into their WAS sorting process.

After a validation period, during which the manufacturer accompanied the operator via regular, progressively spaced visits, the Mistral+ reached its full potential. “Today, this eighth machine is used to separate A-wood, B-wood and, above all, MDF. Its performance positions us very favorably vis-à-vis Ecomobilier throughout the southern Ile-de-France region”, Eddy Dumont is delighted to report.

Pilot” installation

Still in 2014, and still in the spirit of innovation, Pellenc ST was working with Ecofolio (the eco-organization in charge of paper recycling at the time) on the recovery of office paper. “Here again, we were looking for an industrial partner willing to test and validate our technology. We approached Semariv (now Serivel), which operates the selective collection sorting center at Vert-le-Grand. They too played the game, enabling us to add two machines to the flat-body sorting line. One separates paper from cardboard, while the other recovers office paper from JRM,” explains Marc Minassian. This project was awarded the ‘coup de chapeau Ecofolio’ prize at the Salon des Maires 2014.”

Building on these positive experiences, Pellenc ST and Semardel continued their partnership in 2016, on the occasion of the first phase of adapting the selective

collection sorting center was adapted to the extension of sorting instructions (ECT). Selected following a call for tenders, the French manufacturer substituted three of its Mistral+ machines for those of its main competitor, which equipped the original sorting center with six machines.

“Given the constrained environment inherent in modernization projects, we decided to replace one of our machines with a Mistral COMPACT. This machine was perfectly suited to the situation: equipped with easily-integrated modules, it was specially designed for renovation projects where space is at a premium and integration is difficult,” emphasizes Marc Minassian.

Added connectivity

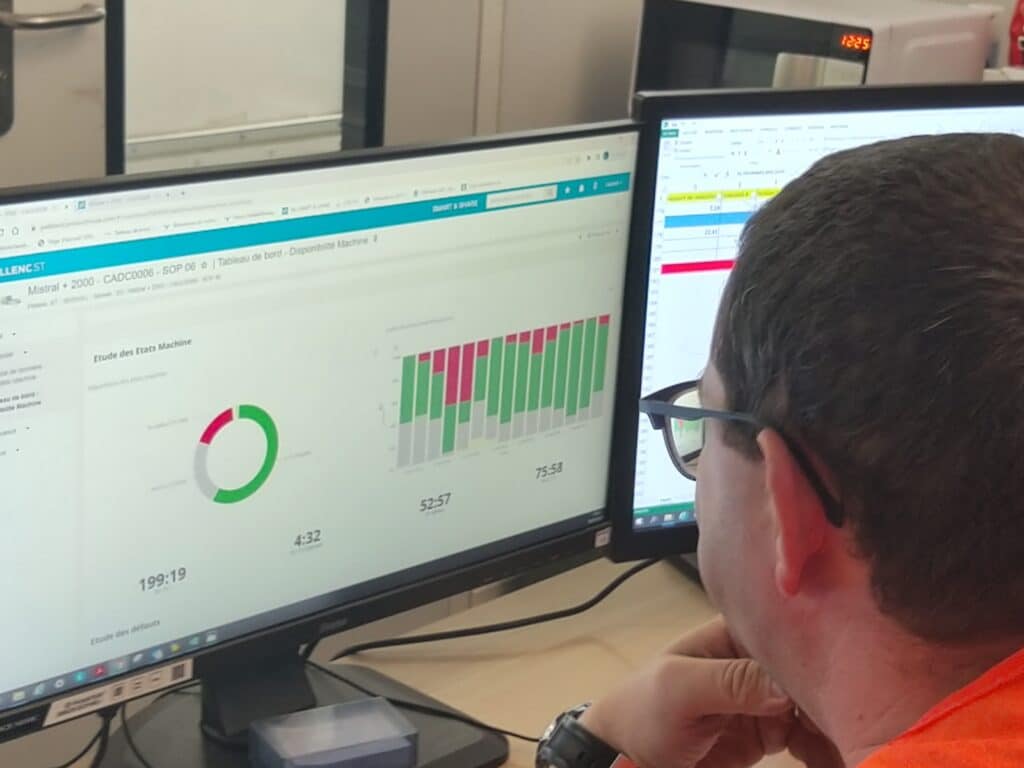

Smart&Share collects and analyzes machine operating data and flow composition in real time.

In 2018, Serivel renewed its confidence in Pellenc ST for the construction of CS2, a new sorting line for selective collection, featuring the latest ergonomic and modern standards. For this project, Serivel and Neos have entrusted Pellenc ST with the supply of twelve Mistral+ optical sorting machines. Finally, in the summer of 2022, the second phase of adaptation of the CS1 line to ECT will be completed, with the last three competing machines being replaced by Pellenc ST Mistral+ CONNECT machines. “With a sorting capacity of 90000 t/year of selective collection spread over two lines (35000t/year for the CS1, 55,000t/year for CS2).

Serivel operates one of the largest units in France, capable of meeting the most stringent demands in terms of the quality of sorted material flows. For example, sorting plastics by resin enables us to produce a mixture of PE-PP-PS, clear PET, dark PET and Citeo’s ‘development flow’,” Eddy Dumont points out.

For his part, Marc Minassian notes that Pellenc ST is now Semardel’s sole supplier of optical sorting technology. “This is recognition of the reliability of our offer. Thanks to feedback from such users, we’ve also been able to upgrade our machines, notably in terms of accessibility and ease of maintenance”, he adds. Far from being on conquered ground, the manufacturer is nonetheless regularly challenged, both in terms of machine availability and the purity of sorted materials.

Service contracts

In order to keep pace with changing ECT flows and customer requirements, the operator needs to be agile in configuring optical sorters, and have machines that can be upgraded. This is exactly what the Smart&Share, available on the twelve machines of the CS2 line, offers,” points out Laurent Gouveia, Sorting Methods Manager for Serivel.

The Smart&Share collects and analyzes machine operating data and flow composition in real time, in order to derive customized performance indicators and production or maintenance alerts. For us, it has become a daily tool to help improve operations.

In addition, each of the entities (Semaval and Serivel) has a service contract for its own fleet of machines, under which Pellenc ST undertakes to monitor and maintain the equipment and regularly upgrade the software. “The machines have been retrofitted,” explains Eddy Dumont. “In fact, compliance with the different CSR recipes we produce relies essentially on the Pellenc ST optical sorters, whose settings are programmed according to the CSR qualities required by our customers”, concludes Manuel Cristino.

Thanks to Hubert de Yrigoyen, Editor-in-Chief of Recyclage et Récupération, for this article.

For more information, contact-us!